唐山鑫虎冶金科技有限公司

- 所在区域:河北唐山遵化市

- 经营性质:有限责任公司

- 企业类型:生产加工

- 注册地:河北省遵化市团瓢庄乡山里各庄村

- 主营产品:直接还原铁生产线,废钢破碎生产线,粒子钢热压块生产线

- 注册资金:人民币 1000 - 5000 万元

- 企业已认证

- 个人实名未认证

- 商家相关产品:

金属压块机海绵铁压块设备

- “铁精粉压块机 2019鑫虎金属压块机参数上线”详细信息

| 产品规格: | 不限 | 产品数量: | 100.00 套 |

|---|---|---|---|

| 包装说明: | 不限 | 价格说明: | 不限 |

| 查看人数: | 261 人 | 本页链接: | https://xinhuyj.b2b168.com/shop/supply/114423378.html |

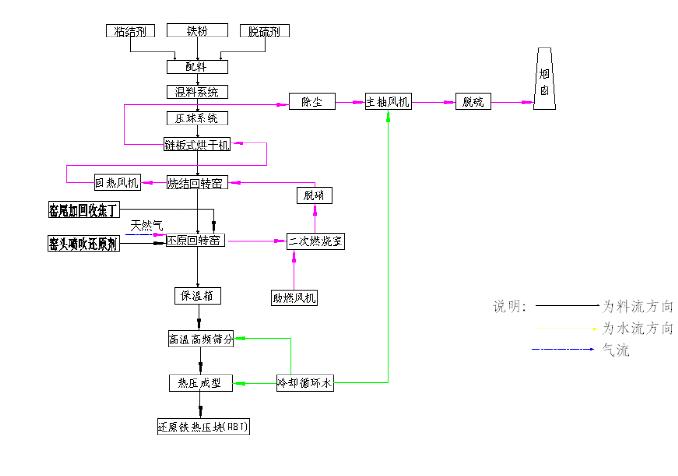

鑫虎钢销、钢渣粒子钢、钢渣精粉、高品位铁粉还原等液压压制成型系统工艺流程 2、Process flow of hydraulic pressing forming system for steel pin, steel slag particle steel, steel slag concentrate powder and reduction of high-grade iron powder (1)工艺流程描述 Process description 钢销、钢渣粒子钢、钢渣精粉、高品位铁粉还原等液压压制成型系统工艺是将钢销、钢渣粒子钢由上料机加入到系统设备,由低温对流烘干器和调温器进行温度控制,对钢渣粒子钢进行烘干,然后经中间转运器输送到液压成型机,经液压按需求调整液压压力(0-315bar动态可调)压制成型后将压制好的粒子钢块由装载机吊运至成品库,期间部分热量由高效换热器进行回收利用,设计有除尘系统对生产过程中产生的废气、粉尘等污染进行环保处理。 Steel pin, steel slag particle steel, steel slag powder, high-grade iron powder reduction and other hydraulic pressing forming system technology is to add steel pin and steel slag particle steel to the system equipment by feeder, temperature control by low-temperature convection dryer and precise thermostat, drying steel slag particle steel, and then conveyed to the hydraulic forming machine through intermediate conveyor, hydraulic pressure adjusted according to demand (0. - 315bar dynamic adjustable) After pressing, the pressed steel particles are hoisted from loader to finished product warehouse, during which part of the heat is recovered and utilized by high efficiency heat exchanger, and a dust removal system is designed to deal with environmental pollution such as waste gas and dust produced in the production process. (2)工艺流程图 Process flow chart (3)主要设备部件包括钢渣粒子钢上料机、低温对流烘干器、调温烘干器、余热回收、除尘器、中间转运器、液压成型机、循环风机、成品输送设备、管道、自动控制系统等。 The main equipment components include steel slag particle feeder, low temperature convection dryer, precise temperature regulating dryer, waste heat recovery, dust collector, intermediate transporter, hydraulic forming machine, circulating fan, finished product conveying equipment, pipeline, automatic control system, etc. 3、安全可靠、优势明显 Safety, reliability and obvious advantages A、渣钢根据粒度不同以不同方式回收利用 Slag steel is recycled in different ways according to its particle size. (1)A1级渣钢,TFe≥80%,粒度>75(mm)为初选渣钢,经电磁除铁器选出,供给转炉炼钢使用。 Grade A1 slag steel with TFe (> 80%) and particle size > 75 (mm) is the primary slag steel selected by electromagnetic iron remover and supplied to converter steelmaking. (2)A2级渣钢,TFe≥80%,粒度10-75(mm)2#棒磨机提纯后,进入2#振动筛,筛上产物,供给转炉炼钢使用。 Class A2 slag steel with TFe (> 80%) and particle size of 10-75 (mm) 2 # bar mill is purified, and then it enters 2 # vibrating screen. The products are screened and supplied to converter steelmaking. (3)B1级磁选粉,TFe≥80%,粒度5-75(mm),经2#棒磨机提纯后,进入2#振动筛,筛下产物,再进行二次筛分,筛上产物,供给转炉炼钢使用。 Level B1 magnetic separator powder, TFe (> 80%) and particle size 5-75 (mm), purified by 2# bar mill, enters 2# vibrating screen, sieves the product, then carries on the second sieve, sieves on the product, supplies the converter steelmaking use. (4)B2级磁选粉,TFe≥42%,粒度 42%) and particle size (< 5 mm), purified by 2 # bar mill, enters 2 # vibrating screen, sieves the product, then sieves the product twice, sieves the product, and returns to sintering. (5)尾渣,MFe<3%,粒度<10(mm),经破碎、磁选、提纯后的产物。 Tailings, MFe < 3%, particle size < 10 (mm), after crushing, magnetic separation, purification products. B、 小颗粒渣钢烧结和直接入炉的弊端 Disadvantages of Sintering and Direct Furnace Entry of Small Particle Slag Steel ●烧结设备大型化和自动化,投资和运行费用较高 Large-scale and automation of sintering equipment, high investment and operation costs ● 由于煤中含硫,所以烧结会排放出有害气体产物二氧化硫,必须进行烟气脱硫处理。 Because of the sulfur content in coal, sulfur dioxide, a harmful gas product, will be discharged from sintering, so flue gas desulfurization must be carried out. ● 由于烧结温度很高,烧结矿不能热送高炉,即使回收部分余热,还是要排出大量废热 Because of the high sintering temperature, sinter can not be hot-fed to blast furnace. Even if part of the waste heat is recovered, a large amount of waste heat must be discharged. ● 氧化铁皮为片状形态,在烧结过程中影响料层的透气性,从而降低烧结产量。并且细小的颗粒容易被气流抽走增加除尘系统负荷。 The sheet shape of iron oxide sheet affects the permeability of the material layer during sintering process, thus reducing the sintering output. And fine particles are easily sucked away by airflow to increase the load of dust removal system. ● 粒子钢直接加入转炉产生较大的火焰和喷溅,存在人员和设备的安全隐患。 Particle steel directly added into converter produces larger flame and splash, which has potential safety hazards for personnel and equipment.

主要经营主要经营:直接还原铁生产线,废钢破碎机,废钢破碎生产线,回转窑还原铁生产线,马口铁破碎设备,金属破碎机,金属破碎设备,金属粉碎机,废钢粉碎设备,钢销热压块生产线,粒子钢热压块设备,粒子钢热压块生产线,海绵铁生产线,还原铁热压块。

单位注册资金单位注册资金人民币 1000 - 5000 万元。

- 我要给“铁精粉压块机 2019鑫虎金属压块机参数上线”留言

- “铁精粉压块机 2019鑫虎金属压块机参数上线”联系方式

- 为您推荐

- “铁精粉压块机 2019鑫虎金属压块机参数上线”相关产品,你也可查看该供应商更多供应产品

-

湖州**反渗透阻垢剂费用

镇江热门阳离子交换树脂

东阳燕窝礼品定制中心批发货源网_八子实业

E1级环保槽木吸音板规格

篷布雨蓬,活动推拉篷中赛兴东莞移动帐篷制作

文登私属燕定制推荐工厂成本_八子实业

额尔古纳孕妇燕窝批发便宜_八子实业

阜阳供应防冻颗粒定制 浩北牌

想要低价颠覆市场 彩柚子文化传播发低价成都大型晚会活动策划

枣阳进口燕窝礼品推荐采购材料_八子实业

晟江机械撬装设备一站式采购,高端定制信誉好、服务优的撬装设备服务

蚌埠热门固体臭味剂报价 浩北牌